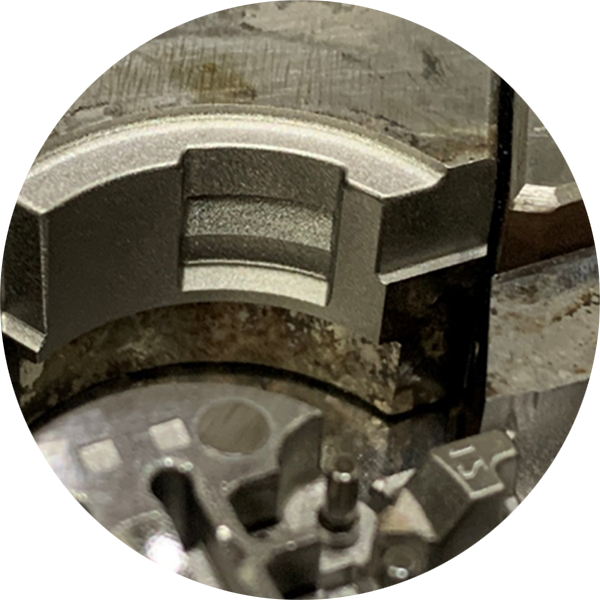

Bleeding

Having trouble identifying your bleeding issue? Check out the common causes and the solutions Nanoplas provides.

Gas Buildup

Is gas build-up causing too much downtime? Try our Zap-Ox product to cut the downtime cleaning in half.

The Latest from Our Blog

Injection Mold Preventative Maintenance Made Easy

Preventative injection mold maintenance doesn’t have to be complicated. It’s about keeping your molds running smoothly and avoiding costly downtime. A consistent maintenance routine protects your investment, improves machine performance, and keeps production moving...

Sustainability in Manufacturing: Extending Mold Life to Reduce Waste

Sustainability in Manufacturing: Extending Injection Mold Life to Reduce Waste Sustainability has become a huge aspect of the manufacturing industry. A 2022 survey found that 68% of manufacturing executives implement more “extensive, corporate-wide sustainability...

Maximizing Plastic Injection Mold Lifespan: Tips and Tricks from Nanoplas Experts

Maximizing Plastic Injection Mold Lifespan: Tips and Tricks from Nanoplas Experts Molds are substantial investments, and their care directly influences your output's consistency, reliability, and excellence. However, plastic injection mold maintenance can easily be...