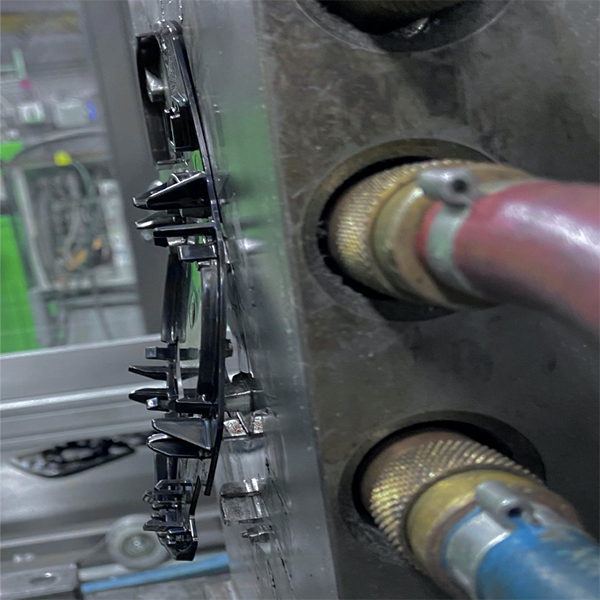

Sticking in Injection Molding

Material sticking to an injection mold can curb your production while simultaneously increasing downtime. Whether it is material, tool design, or other factors that are the issue, Nanoplas has solutions to eliminate sticking while reducing cycle time.

Common Cause:

Material + Other Variables

If you’re applying ample amounts of mold release and still experience sticking, it could be due to the material combined with other variables, such as the temperature, tooling, etc. To get through your run or extend production time, apply a semi-permanent coating.

Solution:

A Nanoplas Coating

Especially ideal for plastic or rubber part release, Nanoplas coatings use polymer technology to create a semi-permanent barrier on the mold’s surface. They have no impact on finished part dimension, don’t migrate to the part surface, and are non-toxic. Additionally, you apply them in-house and they cure in just a few hours.

Common Cause:

Over Applying Mold Release

Over applying mold release to avoid sticking during a product run can lead to more sticking, either because of buildup in the cavity or the creation of a chemical reaction. In either scenario, it’s time to look at an alternative mold release or turn to a coating.

Solution:

Tuff-Kote™

Quick drying, Tuff-Kote mold release offers a longer-lasting release and uses an innovative spray pattern to lay down a thin coat. This helps prevent mold release buildup, especially in the problem areas of a mold.

Solution:

Better Together

When used in tandem, Nanoplas products can help you significantly reduce costs, downtime, scrap, and more. Scientifically formulated, each product is individually effective, so when used together, they enhance mold performance significantly.

66,566% Improvement in Production Capacity with NanoMoldCoating

See Testimonials

No, that’s not a typo. “We built a mold in 2007 for a very large part made of a glass filled polycarbonate, with a foaming agent, and could only produce around 15 parts before the mold began to pick up material on the sidewalls. After exhausting all of our usual tricks, I remembered my PCS salesman had been recommending NanoMoldCoating for problem molds, and reduced cycle times. After applying it according to the directions, we were quite surprised. The mold has run all these years, and usually it requires cleaning/maintenance and recoating after around 8-10 thousand parts.”