Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them. What is an Ejector in Injection Molding? The ejector is the part of the molding process that pushes...

Plastic Injection Molding Defects: Buildup

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them. What is Buildup? Sometimes called gas buildup or plate out, buildup in injection molding is easy to...

Plastic Injection Molding Defects: Burns

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them. What are Burns? Sometimes known as gas traps or the dieseling effect, burns appear as black or brown...

Plastic Injection Molding Defects: Splay

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and offer ways of fixing or preventing them. What is Splay? Splay is a cosmetic defect that occurs in plastic injection molding, when silver or...

Designing Molds for Maintenance & Cleaning

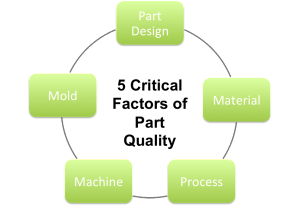

Designing Molds for Maintenance & Cleaning When it comes to designing the mold for a product, there are many factors that have to be taken into account. Part design. materials used for the parts, production volumes, and the list goes on and on. A couple of areas...

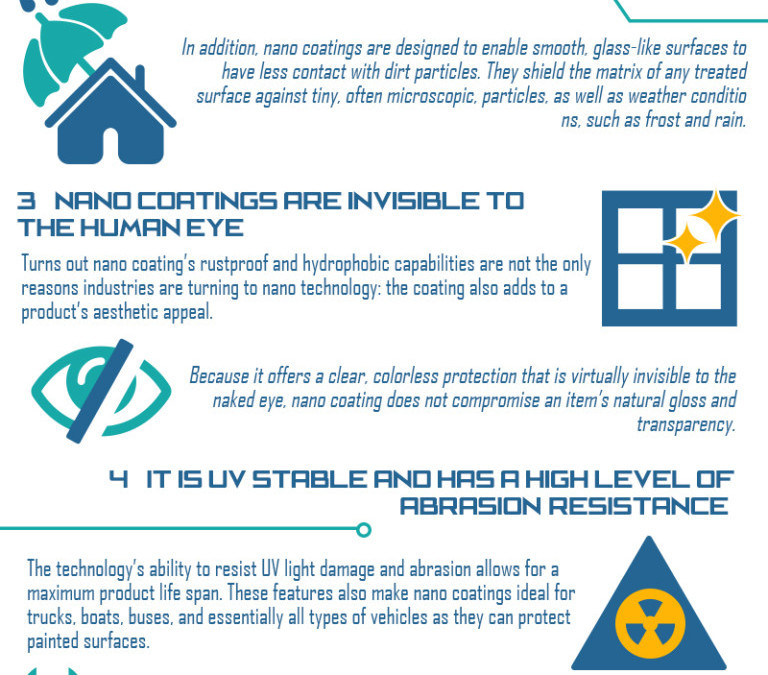

Nano Coating Infographic!

The infographic below is from our friends at Economy Glass in Australia. It does a nice job of explaining nano coatings, and their impact on manufacturing. Check it out:

Addressing Build-Up In Your Molds

Addressing Build-Up In Your Molds There are many potential contributors to in-mold build up. But the impacts that build up can have on your part and your workflow can be significant. Things like sticking, gloss issues, and visual defects are not a positive for...

Design Considerations for In Press Maintenance

Design Considerations for In Press Maintenance Increased productivity and efficiency is a primary goal for almost any molding operation. Performing in mold maintenance is one way to achieve those goals. Obviously, there are a myriad of factors and considerations...

LIFTERS – Their Impact on Tool Maintenance, Repair & Molding

Lifters are a hot topic in injection molding, and Randy is working hard to address many of the major issues being brought up. In this recent article on MoldMakingTechnology.com, he identifies many of the issues with lifters and also explains why lifters are used,...

Injection Mold Tooling – Dealing with Lifters

There are many variables and impacts that lifters can have on your molding process and final parts. Randy Kerkstra recently published an article at the Plastics Technology site (ptonline.com) that went into more detail on lifters and was a continuation of his...

The 6 Steps for Scientific Molding

Optimizing The Molding Process The use of Scientific Molding has had a dramatic impact on the efficiency of molding operations. The following 6 steps should be considered to help optimize the process robustness of your molding operation. Viscosity Curve The scientific...

The Industrial Science of Injection Molding

Taking Injection Molding To The Next Level When an industrial science approach is applied to the molding process, it takes injection molding to a higher level of precision and more importantly, repeatability. It is especially relevant and applicable for complex and...

Material Selection Considerations for Injection Molding

Material selection is one of the most crucial factors when developing an injection mold design. There are a lot of excellent material suppliers offering quality materials for the injection molding process. Many also offer different grades or blends of materials to...

SMED – Single Minute Exchange of Die and Injection Mold Maintenance

How SMED and Mold Maintenance Work Together Time is money in the production business and the more you waste, the more you lose. The Single-Minute-Exchange of Die (SMED) methodology may allow you to successfully implement a lean production process in your injection...

For Manufacturing, It Looks Like Robots Are Benevolent

In some industries, the rise of machines more capable of performing complex tasks is taking the place of human workers. Here's an article from BetaBoston claiming that in the manufacturing industry things are different... "It appears the manufacturing industry may be...

Environmentally Friendly Plastic Injection Molding

"In today’s world, the green movement is more important than ever. No matter what the industry, it’s a company’s duty to make changes and choices that support the environment." Here's a great article from The Rodon Group about working with injection molders that are...

What You Need to Know About Rust Preventatives

Your mold maintenance strategy should include rust prevention. If you do not use the right methods to prevent your tooling and mold from rust, you may as well put paid to your manufacturing process. Once rust affects your molds and tooling, it will be quite expensive...

5 Tips to Improved Manufacturing Quality

5 Tips to Improved Manufacturing Quality "There is no better cost to eliminate than the cost of poor quality." Here's a great article from Industry Week that outlines 5 steps to improving manufacturing quality. Some of them are organizational tips; others stress the...

What Are the Benefits of Lean Manufacturing?

Why implement lean manufacturing? Here's a quick article that outlines the benefits of the manufacturing mindset that is changing the way manufacturing is being done. The implementation of lean manufacturing through trying to make value flow at the pull of the...

Molding Complex Parts: The Process

Many complex and critical parts of machinery are difficult to make since they have challenging shapes and sizes. Furthermore, some injection molding companies do not always have the expertise, knowledge and equipment to make these complex parts. That's why, when...