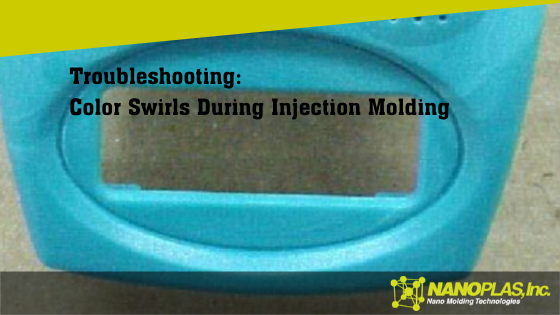

When color isn’t evenly distributed throughout a part, appearing as streaks, swirls or patches of discolored material, you’re probably looking at color swirls. Also known as streaking, color streaks and marbling, color swirls are occasionally misidentified as black and brown streaking, so it’s important to determine which defect you’re dealing with as the first step in your troubleshooting.

If misidentified, many of the solutions to color swirls will actually exacerbate the black and brown streaking, so accurately identifying the problem is a must.

What Causes Color Swirl Problems in Plastic?

When determining the cause—and thus solution—of color swirls, the first thing you need to know is when the problem is occurring. If you’re seeing color swirls after changing from one color to another, the solution won’t be the same as random or always-present swirls.

If the color swirls only appear after changing colors or materials, the culprit probably deals with your purging procedures. Changeovers have to be done correctly or you may be stuck with color swirls for hours.

Color Swirls Troubleshooting Chart

| Machine | Material | Molding Process |

|---|---|---|

| Screw design | Color concentrate | Low back pressure |

| Inadequate back pressure | Contamination | Fast screw speed |

| Hang-up in screw or barrel | Raw component issues | Low melt pressure |

How to Prevent Color Swirls in Injection Molding

Within the molding process, you need to pay extra attention to back pressure, screw speed and melt temperature. If the back pressure is too low, the material and color concentrate won’t mix properly, leading to color swirls.

Similarly, a fast screw speed can lead to color swirls. The longer the screw rotates, the better the color mix will be, but if screw recovery is too fast, you’ll likely find good results in slowing the speed.

You could be dealing with a melt temperature that’s too low and, since the melt temperature is impacted by so many other factors, it’s important to know exactly what your melt temperature is and that it’s within the recommended range for your material.

If the issue is with the machine, check out the screw design, back pressure and possible hang-up in the screw or barrel, which can prevent it from cleaning out well during color changes. A general-purpose screw design isn’t the best option for color and material mixing, so make sure you’re using a melt-quality screw. If you don’t have enough back pressure, you’ll likely find poor color mixing, which leads to color swirls.

Color swirls emanating from material issues can be due to an incompatible material-to-concentrate relationship, which could be as simple as using a concentrate that’s intended for a different material. You could also be dealing with contamination, which can cause a host of other problems, or a raw component issue.