High Temperature Grease in Injection Molding

In injection molding, moving components such as slides, pins, and bushings operate under high heat and constant friction. Without proper lubrication, these parts can seize, gall, or wear out quickly, leading to costly downtime and reduced mold life. High temperature grease is specially formulated to withstand the extreme conditions of molding environments; resisting breakdown, preventing metal-to-metal contact, and ensuring smooth operation cycle after cycle.

Nanoplas grease solutions are engineered to provide lasting protection even in continuous high-heat applications. They maintain lubricating integrity, resist washout, and reduce the need for frequent reapplication, keeping molds running efficiently and minimizing unplanned maintenance.

FAQs

What is High Temp Grease Used for?

High temperature grease is used to lubricate moving components that operate under extreme heat and friction, such as ejector pins, slides, bushings, and other precision parts in injection molding. It maintains its lubricating properties at elevated temperatures, preventing metal-to-metal contact, reducing wear, and ensuring smooth mold operation. This specialized grease resists breakdown, contamination, and washout, making it ideal for high-demand, continuous production environments.

How Often Should High Temp Grease Be Applied?

The reapplication schedule depends on production volume, mold design, and operating conditions. While some molds require lubrication every shift, high-performance high temp greases can significantly extend maintenance intervals.

Is High Temp Grease Compatible with All Mold Materials?

High temperature grease is used to lubricate moving components that operate under extreme heat and friction, such as ejector pins, slides, bushings, and other precision parts in injection molding. It maintains its lubricating properties at elevated temperatures, preventing metal-to-metal contact, reducing wear, and ensuring smooth mold operation. This specialized grease resists breakdown, contamination, and washout, making it ideal for high-demand, continuous production environments.

Common Cause:

Thermal Breakdown

Standard lubricants can degrade rapidly when exposed to the extreme operating temperatures found in injection molding, especially during long production runs. As grease breaks down, it loses viscosity and protective properties, leading to increased friction, wear, and potential part damage. Using a dedicated high temp grease ensures lubrication remains stable and effective, even under sustained heat.

Solution:

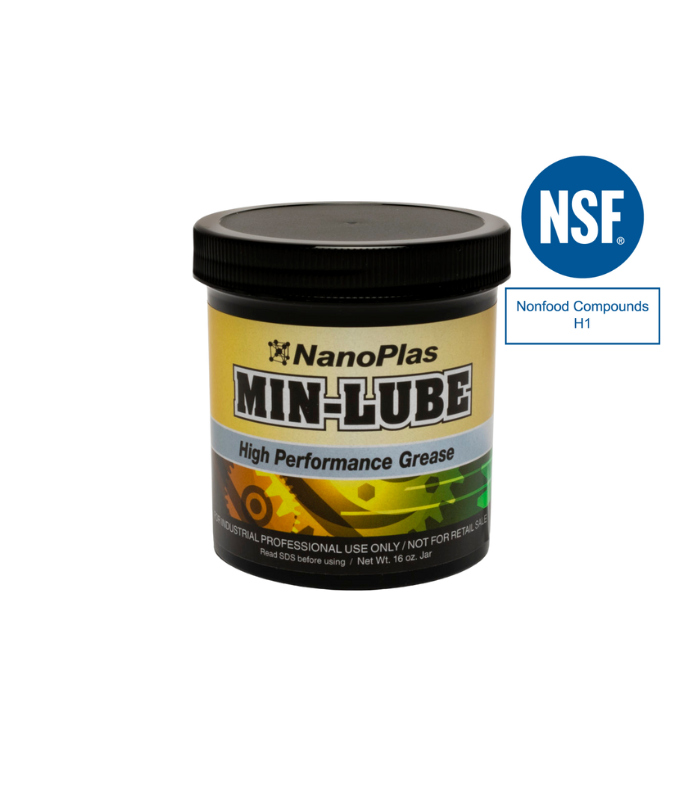

MIN-LUBE™

MIN-LUBE High Performance Grease can withstand higher temperatures, so it won’t break down and bleed out.

Common Cause:

Contamination from Resin or Debris

During molding, resin particles, dust, and other contaminants can enter moving mold components, mixing with the grease and reducing its effectiveness. Over time, this contamination creates an abrasive paste that accelerates wear. A high temperature grease with strong adhesion and contaminant resistance, like Nanoplas Min-Lube products, helps keep components clean, lubricated, and protected.

Solution:

Min-Lube™

Min-Lube High Performance Grease has strong adhesion, anti-wear additives, and a low coefficient of friction, so the thinnest of coatings is enough to get the job done, and it’ll stay put.

Better Together

When used in tandem, Nanoplas products can help you significantly reduce costs, downtime, scrap, and more. Scientifically formulated, each product is individually effective, so when used together, they enhance mold performance significantly.

Medbio cut preventive maintenance by over 560 hours per year by switching to Min-Lube.

Partial PM intervals doubled and Full PM intervals nearly tripled, driving major cost and time savings.