Causes for Black Specks in Your Injection Molds

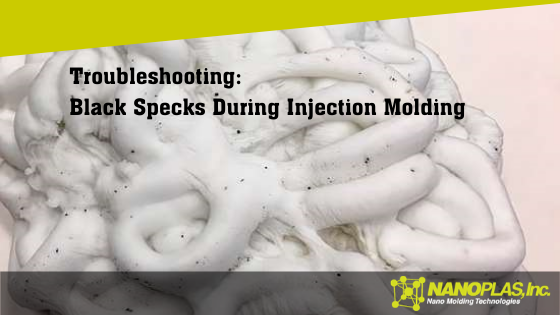

When you see black or brown specks on your molded part, you’re probably dealing with material that has been severely degraded. Sometimes called carbon buildup, black specks are sometimes mistaken as material contamination. While contamination can be a cause, you’ll need to look closer to know for sure.

What Causes Black Specks?

Most often, black specks are a sign the material has been degraded to a charred state, which usually means the material has been at temperature for too long. However, there are a number of things related to the process, mold, machine and material that can lead to black specs.

Black Specs Troubleshooting Chart

| Mold | Machine | Materials | Molding Process |

|---|---|---|---|

| Dust from wear surfaces | Hang-up areas, screw, barrel, etc. | Contamination | Improper machine shutdown |

| Hot runner temperatures | Barrel heater control | Wrong material | High melt temperature |

| Hot runner hang-up areas | Regrind fines | Long residence time |

How to Prevent Black Specks in Injection Molding

The first thing you want to look at is the residence time. When a material spends too much time at temperature, it’s prone to black specks. It’s important to note, though, black specks come from a time-and-temperature problem. That is, we need to look at not only the residence time but also the heat history on the material.

Properly purging the machine at shutdown and ensuring the melt temperature isn’t too high (an issue that itself probably won’t cause black specks but can definitely contribute to the likelihood of a material to degrade) will help mitigate the risk of material degradation.

While residence time is the most frequent root cause of black specks, don’t overlook debris and dust from mold wear surfaces. Miter locks, wear plates and shutoff surfaces on molds can create metal dust and get into the mold cavity. If molded into the surface of a light-colored part, the dust will show up as black specks. Keeping the mold clean is crucial in preventing dust from creating issues with the part.

If you are unable to solve the issue right away, Zap-Ox is an excellent product for removing gas and surface stains like black specs. It is a cream cleanser that you apply to the area, let sit for a minute or two and then move around. It will bring the stain completely out of the substrate without any scrubbing.