by Admin | May 13, 2019 | Plastics, Recent Posts |

One of the most important aspects of injection molding, or anything involving machining, is making sure machines are running at peak performance. Any downtime cuts into efficiency and, ultimately, the bottom line. Prolonged downtime can lead to serious problems with customers and nobody wants that.

Injection mold maintenance itself requires machine downtime, but when you plan for it, you’re able to maintain efficiency without the fear of unexpected and potentially disastrous downtime that may arise from failing to maintain your machines.

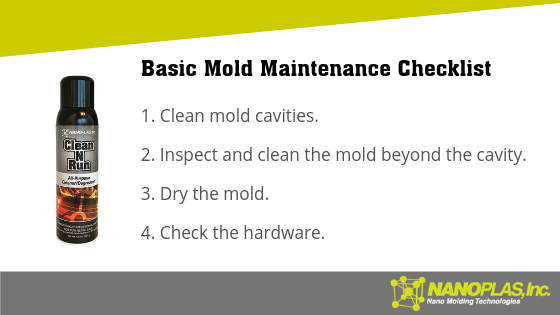

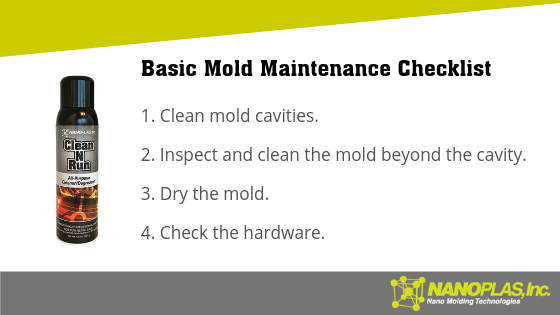

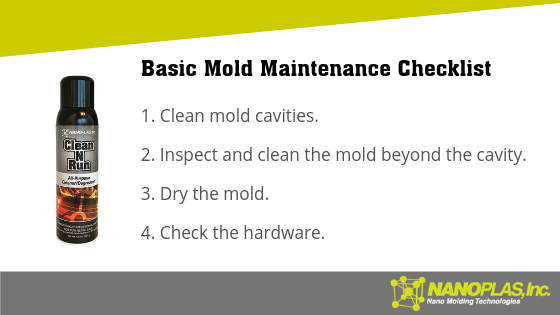

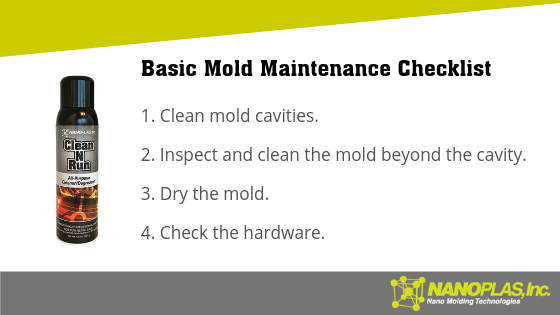

Basic Injection Mold Maintenance Checklist

Before and after every cycle, you should do a basic maintenance check on your mold. This ensures you’re keeping the mold free of potentially harmful debris, which means your parts will come out just as they’re supposed to.

1. Clean Mold Cavities.

First, use a solvent like Nanoplas Clean-N-Run to eliminate any residue that may be left behind in the mold. Spray it on, gently wipe the cavities and dry the mold. Start from the top of the mold and spray in a top to bottom motion as you move down the mold. If the mold needs further cleaning repeat the process or use a cloth to scrub hard to move contaminants. Once done cleaning dry the mold.

Next, hit the molds with compressed air. This helps dry the mold after using Clean-N-Run and also gets deeper into the mold to eradicate any additional debris you couldn’t otherwise reach.

2. Inspect and Clean the Mold Beyond the Cavity.

Debris and water are just as detrimental in the runners and sprues as they are in the cavity and you should never neglect these areas. Use Nanoplas Mold Brite or Clean-N-Run here as well, then follow it up with compressed air. Every part of the mold should be clear of debris before you run another cycle.

3. Dry the Mold.

Part of the compressed-air benefit is aiming toward completely drying the mold, but this is an important point, especially before storing the mold: the mold needs to be completely dry. If any water is left behind in a metal mold, you’re at risk for rust, which can cause a slew of problems. Rusty molds create more rejected pieces and are also prone to failing completely. Prevent these problems before they start by making absolutely sure your molds are dry.

4. Check the Hardware.

Make sure everything is in working order with your bolts, screws, plates and anything else fastening your mold. Nothing should be loose and there should be very little wear on these components.

Advanced Injection Mold Maintenance Checklist

Even with daily or twice daily mold machine maintenance as discussed above, the reality is certain parts will eventually wear out and need to be replaced. In addition to following the basic injection molding maintenance checklist before and after every cycle, you’ll want to do deeper inspections at longer intervals.

You should perform this maintenance at regular intervals determined by what type and how many cycles you’re running.

Check Ejection Components

All ejection components, including ejection pins, should be inspected. If you notice any damage, replace the parts. Also, make sure all the parts are appropriately lubricated. Do this every 10,000 cycles or so.

Additionally, Check All Non-Ejection Components

You don’t need to do this as frequently (maybe every five to 10 times you check the ejection components), but your inspections should never be limited to only ejection components. All parts related to the mold need to be checked for wear, damage and lubrication, including gaskets, valves and springs.

The Value of Preventive Injection Mold Maintenance

As discussed earlier, there is a cost associated with preventive maintenance: downtime of your machines and the manpower to perform the checks. However, this cost is virtually nonexistent when compared to the much higher cost of unexpected and potentially prolonged downtime, rejected parts and other hassles that hinder efficiency.

By getting in the habit of performing regular maintenance checks, you can keep your machines—and your business—running efficiently. Learn more about the different offerings that Nanoplas provides to keep your mold machinery maintained and in good shape here.

by Admin | Mar 12, 2019 | Plastics |

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them.

What is an Ejector in Injection Molding?

The ejector is the part of the molding process that pushes the part out of the mold when it’s time to do so. Because of the ejector itself and the ejector pins, there are several areas that could result in the mold sticking to the ejector.

What Causes Parts to Stick on the Ejector?

This is one of the most difficult injection-molding defects to diagnose because there are so many possible reasons a part would stick to the ejector. In the molding process itself, multiple settings could be off one way or another. Second-stage pressure, mold temperature, cooling time, melt temperature, and possibly a fast injection speed.

When you’re looking at the molding process as the culprit, you’ll likely end up with a tight processing window. At that point, you should look into improving the mold itself for the best results.

Table 36.1 Part Sticking on Ejector Troubleshooting Chart, found in Injection Molding Advanced Troubleshooting Guide: The 4M Approach (p. 345)

| Molding Process | Mold | Machine | Material |

| Low or high second-stage pressure | Surface finish | Machine performance | Material type |

| Low or high mold temperature | Lack of ejection | Ejector Plate | Moisture content |

| Long or short cooling time | Lack of draft | Robot handling | Release agents |

| Fast ejection speed | Buildup | | |

| Low or high melt temperature | Slides or lifters | | |

| Damage, erosion, or burrs | | |

How to Prevent Parts from Sticking on the Ejector

When you use our Heat Cure™ and Quick Cure coatings—which are also ideal for preventing pin push—you get extraordinary release characteristics, preventing the ejector pins from sticking in the plastic.

Because injection mold buildup could also be an issue with sticking parts, you could also try one of our mold cleaners like Clean-N-Run, Mold Brite, Power Clean, Kleen All, and Zap-Ox.

Feel free to contact us if you have questions about our products and how they might solve your injection-molding problems.

Stay tuned for future installments of our plastic injection molding defects series.

Source: Injection Molding Advanced Troubleshooting Guide: The 4M Approach by Randy Kerkstra and Steve Brammer.

by Admin | Mar 4, 2019 | Plastics, Recent Posts |

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them.

What is Buildup?

Sometimes called gas buildup or plate out, buildup in injection molding is easy to see on the cosmetic surfaces of the part, appearing rough. You’ll know buildup when you see it as it’s not confused with any other injection molding defects.

Buildup can cause further problems when it occurs in the mold venting, as it makes it harder for the mold to vent gas out of the cavity, which can lead to issues like splay.

What Causes Buildup?

In most cases, buildup forms when volatiles leave the plastic and collect on the surface of the mold. There are several reasons this could be happening, but most of the time, you’ll be able to solve your buildup problem if you can figure out what’s causing the excess volatiles and whether or not those volatiles can be better vented.

If the melt temperature is too high, excess gas can be generated and degrade the materials. Along these lines, too much shear can lead to too high of a melt temperature, which can lead to the gas buildup.

Most of the time, buildup is caused by poor venting. If the mold isn’t vented well enough, the volatiles from the plastic get trapped, directly leading to buildup problems.

Table 19.1 Buildup Trouble Shooting Chart, found in Injection Molding Advanced Troubleshooting Guide: The 4M Approach (p. 174)

| Molding Process | Mold | Machine | Material |

| high melt temperature | vents | machine performance | regrind |

| excess shear | | | moisture content |

| | | material type |

| | | additives |

How to Prevent Plate Out in Injection Molding

If you’ve determined your buildup is caused by a venting issue, make sure all vents are open and are deep enough with a large enough land length.

Nanoplas mold-release sprays, coatings, and cleaners are essential to preventing buildup. Our mold-release sprays and coatings work against buildup the same way they work against pin push: exceptional release characteristics allow the mold to eject without sticking, preventing buildup in the process.

Some competing sprays go on heavy and make it difficult to run the mold effectively, but our sprays and coatings eliminate excess mold release without leaving any residue.

To eliminate buildup, Mold Brite, Power Clean, and Kleen All are excellent choices in mold cleaners. The ultimate cleaner: Zap-Ox, which will clean buildup even when you thought there may not be a solution.

Feel free to contact us if you have questions about our products and how they might solve your injection-molding problems.

Want to learn more? Check out these other great articles that solve common injection mold issues:

Source: Injection Molding Advanced Troubleshooting Guide: The 4M Approach by Randy Kerkstra and Steve Brammer.

by Admin | Mar 4, 2019 | Plastics, Recent Posts |

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them.

What are Burns?

Sometimes known as gas traps or the dieseling effect, burns appear as black or brown deposits, sooty like charcoal, both on the part and the mold surface.

What Causes Burns?

There’s a good reason burns are also called gas traps in injection molding: they’re caused by trapped gases. When gases get trapped during mold filling, high pressures can cause ignition, which leads to the plastic burning. Burns in injection molding are, quite literally, burns.

To determine the cause of your issue, first determine where the gas is coming from, and then ask why isn’t the gas escaping the mold?

You could be looking at fill velocity, melt temperatures, back pressures, or decompression among the molding process. The machine itself could have buildup, damaged parts, or even the wrong screw design. The material may struggle with its moisture content or additives.

The most common culprit deals with mold venting issues. If you determine this is the cause of your problem, do not try to process around a tooling issue. Address all tooling issues before adjusting the process. Many of the other problems are either caused by or made worse by venting. This is the first thing you should check.

Table 20.1 Burns Troubleshooting Chart, found in Injection Molding Advanced Troubleshooting Guide: The 4M Approach (p. 182)

| Molding Process | Mold | Machine | Material |

| too fast fill velocity | venting | buildup on screw, end cap, etc. | moisture content |

| high melt temperature | grease, oil, or other contamination | screw design | type |

| high back pressure | | barrel heater control problems | additives |

| decompression | | damage to screw, barrel, tip, etc. | |

How to Prevent and Remove Burn Marks in Injection Molding

It bears repeating: if you have a venting issue, do not process around it. When your mold isn’t venting well enough, it can make any of the other causes of burns worse. When you improve your mold venting, you eliminate most burning issues.

Also, reach for the Cera Lube. Because over-greasing and grease breakdown can cause burning, Nanoplas Cera Lube, which neither breaks down nor bleeds, is the best solution.

Feel free to contact us if you have questions about our products and how they might solve your injection-molding problems.

Stay tuned for future installments of our plastic injection molding defects series.

Source: Injection Molding Advanced Troubleshooting Guide: The 4M Approach by Randy Kerkstra and Steve Brammer.

by Admin | Nov 29, 2018 | Plastics, Recent Posts |

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and offer ways of fixing or preventing them.

What is Splay?

Splay is a cosmetic defect that occurs in plastic injection molding, when silver or white streaks appear on the surface of the part.

It can be difficult to determine what is truly splay, as its appearance is very similar to other defects. Lookalikes include surface scratches, scuffs, flow lines, delamination from contamination, and flaking (also known as cold slugs).

What Causes Splay?

There are many possible culprits for the appearance of splay. Chapter 42 of Injection Molding Advanced Troubleshooting Guide: The 4M Approach outlines a specific troubleshooting method for determining the source and correcting it. The defect could be due to any number of issues with the molding process, the mold itself, the machine, or the material.

Table 42.1 Splay Troubleshooting Chart, found in Injection Molding Advanced Troubleshooting Guide: The 4M Approach (p. 414)

| Molding Process | Mold | Machine | Material |

| drying | venting | screw design | contamination |

| high melt temperature | hot runner temperatures | temperature control | excessively wet |

| decompression | cold slug wells | damaged components | wrong material |

| back pressure | sprue and nozzle tip orifice | cracked feed throat | blowing agent |

| screw recovery rate | sharp corners | lack of process control | |

| residence time | gate flaking | | |

| screw recovery | lubricants | | |

| feed throat temperature | cracked mold | | |

| inconsistent material feed | leaking air | | |

| Venturi effect | | |

To begin, determine how the defect appears on the parts. If the marks appear consistently in the same location on parts, the problem is likely stemming from the mold itself. If the defect is all over the part and/or appears in random places, that usually means the issue comes from the molding material or process.

We recommend referencing the Troubleshooting Guide to help you fully understand which of the above may be causing the defect and how to best fix it. At Nanoplas, we are particularly familiar with lubricants’ contribution to splay through our discussions with molding professionals over the years, so we’ll explore ways to address this possible culprit in the rest of this post.

Over-Lubricated Molds Can Cause Splay

If the defect appears immediately after the mold has come back from the toolroom, it may be due to too much grease or lubricant being applied to the mold. In this case, grease from the lifters or ejector pins can bleed onto the core surface, get pulled onto the surface, and leave splay marks or streaks.

Similarly, lubricants and metal protectants can become trapped in mold inserts and bleed out, getting pulled onto the mold surface and causing splay.

“Less is more” when it comes to applying mold maintenance products in a way that won’t cause problems. You may need to wipe out the excess lubricant, even disassembling the mold as necessary to get all the excess. For more information related to mold maintenance, read: How to Properly Apply Injection Mold Coating.

If decreasing the amount of grease or lubricant causes wear or other issues, you may want to try higher performing mold maintenance products that can do the job with less volume per application.

How to Fix Splay

Again, be sure to fully troubleshoot each key area of injection molding—the molding process, mold, machine, and material—to find the true source and determine the best course for addressing your unique situation.

If you suspect the mold grease is causing the issue, it may be time to try something new.

Switch Mold Maintenance Products

Nanoplas has several products that can eliminate splay caused by over-lubrication.

Some rust preventatives can use a heavy wax or too much solvent, making it necessary to clean the mold before use to prevent splay caused by the bleeding or breakdown of grease. The Nanoplas family of rust preventatives are truly “dry” and leave a light film that will not bleed or break down grease. On a typical startup, the Nanoplas rust preventatives will be gone in 2-4 shots.

If grease is getting into the molding area, that means it is breaking down from a rust preventative, cleaner, or heat. Nanoplas greases do not break down and will not bleed into the molding area like other greases. This eliminates grease from the splay equation.

Feel free to contact us if you have questions about our products and how they might solve your injection molding problems.

Want to learn more? Check out these other great articles that solve common injection mold issues:

Source: Injection Molding Advanced Troubleshooting Guide: The 4M Approach by Randy Kerkstra and Steve Brammer.

by Admin | Feb 21, 2016 | Manufacturing, Plastics, Recent Posts |

The infographic below is from our friends at Economy Glass in Australia. It does a nice job of explaining nano coatings, and their impact on manufacturing.

Check it out: