by Nanomold Coating | Sep 21, 2023 | Recent Posts |

Unveiling the Hidden Culprits: Nanoplas Coatings – Your Guide to the Root Causes of Sticking Issues

Innovation drives the world forward. For over two decades, Nanoplas has stood at the forefront of innovation, revolutionizing the plastic injection mold industry with its products. Our foundation is built on a commitment to reimagining mold maintenance, improving efficiency, and bringing about change in areas where stagnation has become the standard. This commitment is echoed today as we dive into one of the most notorious challenges in our industry: sticking issues in injection molding.

The Sticking Point: A Persistent Problem

Sticking in injection molding isn’t just an annoyance; it’s a production hindrance and a root cause of increased downtime. You might be familiar with this scene: you’ve applied layers of mold release, yet the material still sticks to the mold. What gives?

Common causes can be a low-quality blend of the material itself combined with external variables like temperature or tooling. On some occasions, even over-applying mold release to prevent sticking can paradoxically lead to more of it. Whether it’s a buildup in the cavity or an inadvertent chemical reaction, the problem remains, and the solution seems elusive.

Nanoplas Coatings: The Unveiling Begins

Enter Nanoplas coatings.

Leveraging the power of nanotechnology, our coatings present a proactive approach to address sticking issues. Think of it as a semi-permanent guardian for your molds. These coatings create a resilient barrier on the mold’s surface, ensuring exceptional part release. And the benefits don’t just stop at release. Nanoplas coatings ensure:

Maintained Precision: Our coatings guarantee that there is no impact on the finished part dimension.

No Migration: Worries about residues migrating to the part surface? Lay them to rest. Nanoplas coatings stay where they’re supposed to, ensuring your finished parts are free from unwanted traces.

Safety First: We understand the importance of safety in the production process. Nanoplas coatings are non-toxic, ensuring a safe environment for both the workers and the end products.

Moreover, with the convenience of in-house application and just a few hours of curing time, these coatings seamlessly integrate into your production process, eliminating sticking issues without introducing new challenges.

Nanoplas’ Vision for Seamless Injection Molding

Material sticking in injection molding isn’t just a challenge—it’s a riddle. A riddle that has multiple answers, hidden culprits, and variables. With Nanoplas coatings, we’re not just providing an answer; we’re helping you understand the question, unveil the hidden culprits, and elevate your production to unparalleled efficiency.

Because at Nanoplas, we don’t develop products based on what we think customers need. We innovate based on what we learn from you to make your processes more efficient.

Contact us today to learn more about our coatings and how they can help you with sticky issues.

by Nanomold Coating | Sep 15, 2023 | Recent Posts |

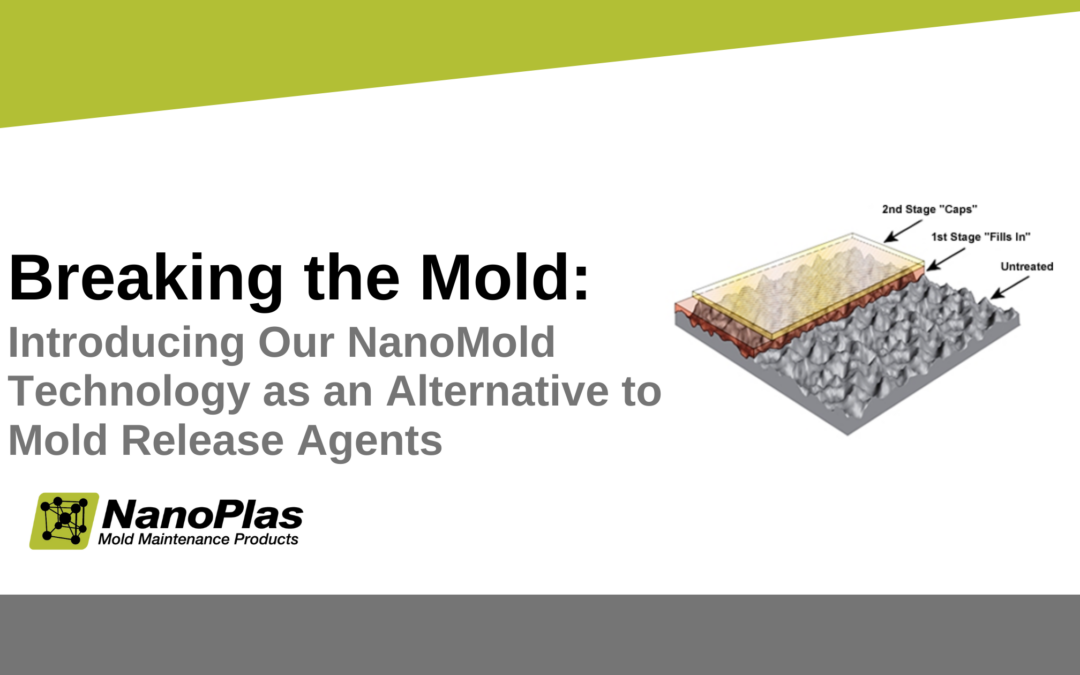

Breaking the Mold: Introducing Our NanoMold Technology as an Alternative to Mold Release Agents

In the world of injection molding, where precision meets productivity, the battle against sticking molds and sluggish releases has been ongoing. Traditional mold release agents have played a pivotal role in this industry, but most solutions have not kept up with the times. Enter NanoMoldCoating, a superior alternative from Nanoplas that represents increased productivity, precision, and flexibility.

Redefining Mold Release: From Agents to Coatings

Mold release agents traditionally help release parts from molds, but they often need reapplication and can hinder subsequent processes like painting. Nanoplas’ patented solutions, NanoMoldCoating and NanoMoldRelease, address these issues using advanced nanotechnology.

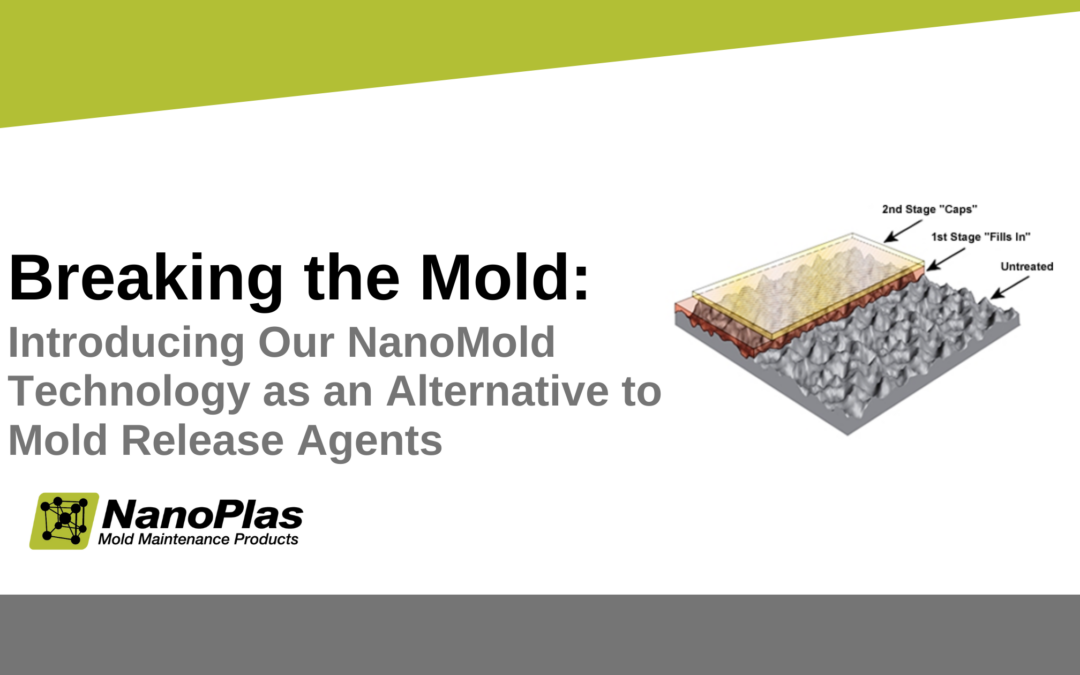

Utilizing this technology, NanoMoldCoating creates a thin, semi-permanent barrier on mold surfaces. This barrier self-assembles to form a nano-mesh that repels fluids and allows gases to escape, making the coating breathable. At only 100-200 nanometers thick, it ensures smooth part release without impacting the dimensions. The 3-4 hour application process ensures the coating firmly attaches and is free of imperfections. Moreover, it’s compatible with processes previously disrupted by traditional agents, such as painting, and is suitable for environments where silicone products are banned.

Advantages That Mold the Future

The benefits of NanoMoldCoating are extensive and will make you say goodbye to traditional mold release agents for good:

Productivity Amplified: Say goodbye to frequent reapplications and hello to more parts per hour, per shift, and per day. NanoMoldCoating enhances productivity significantly, optimizing your operations for unprecedented efficiency.

Flexibility Unleashed: NanoMoldCoating can be swiftly and conveniently applied in-house, eliminating the need to send tools to secondary vendors for costly coatings. Take control of your operations while putting money back into your pocket.

Material Flow Mastery: With its low coefficient of friction, NanoMoldCoating goes beyond simple release – it enhances material flow within molds, leading to improved part packing capability while ensuring smooth part release.

Precision Perfected: Witness a reduction in injection pressure and temperatures, a liberation from streaking and drag marks during mold filling, and a powerful corrosion inhibitor – all thanks to NanoMoldCoating’s expert engineering.

Versatility Redefined: Whether it’s thermoplastic or rubber, NanoMoldCoating is your go-to release solution. Its flexibility and non-migratory properties make it an invaluable asset across diverse applications.

Meet the Lineup

The Nanoplas coating lineup is as diverse as it is effective:

HC™ Heat Cure: The longest-lasting of the Nanocoatings, HC Heat Cure creates a semi-permanent mold surface barrier for exceptional release.

HCF™ Heat Cure FDA Compliant: Complies with FDA regulations while delivering the same remarkable mold release benefits as HC.

QC™ Quick Cure: An on-press solution for quick and effective plastic part release.

QCRU™ Quick Cure Rubber Formula: Designed specifically for rubber part release, this quick-cure formula is a game-changer for rubber applications.

QCSI™ Quick Cure Silicone Formula: Tailored for silicone part release, QCSI Quick Cure is your answer to seamless silicone molding.

Embrace the Future of Mold Release

It’s time to say goodbye to the limitations of traditional mold release agents and make the switch to nanotechnology from Nanoplas. Experience the difference for yourself. Order your free samples and break the mold with Nanoplas.

by Nanomold Coating | Jul 6, 2023 | Recent Posts |

In injection molding, precision, efficiency, and cleanliness are key. A high standard of cleanliness ensures the production of top-quality components and prolongs the lifespan of expensive equipment, ultimately benefiting the bottom line. Any build-up of stains or oxidation in your molds can drastically impact the production process, resulting in defective products and frequent, costly maintenance routines. Enter Zap-Ox™, a state-of-the-art stain and oxidation cleaner from Nanoplas. Zap-Ox™ removes gas stains, rust, weld scale, and other types of oxidations on plastic injection molds or any other metal substrates. Zap-Ox™ NG provides the same cleaning power as the original, but this non-grit formula is specifically designed for polished and textured surfaces.

Designed with the complex needs of the injection molding industry in mind, Zap-Ox™ revolutionizes the cleaning process and optimizes operations. Let’s look at the benefits this impressive solution brings to the table.

Efficiency in Cleaning

By employing a scientifically advanced formula, Zap-Ox™ clears surface-level stains and effectively eliminates oxidation. Traditional cleaning agents often struggle with persistent stains and require considerable manual effort and time, but Zap-Ox™ effortlessly tackles these challenges, drastically reducing downtime in production cycles. By applying a thin coat of the cleaner onto the stained surface, Zap-Ox™ will go to work and pull the stain out of the metal without etching the surface. Where most cleaners require surface scrubbing, Zap-Ox™ removes most stains without scrubbing.

For example, Ess Tec, Inc., a plastic injection molding company in Holland, Michigan, uses Zap-Ox™ to clean gassing and burn marks at the end of the fill. In the past, they had to pull the tool and stone polish or bead ballast to remove the gassing from the texture. Now, Zap-Ox™ removes the rust from high humidity and condensation on the cavity steel. This saves hours of tool maintenance work.

Zap-Ox™ ‘s high cleaning efficiency translates into tangible benefits, delivering exceptional value and contributing to the optimization of injection molding processes.

Extended Molds & Tools

A build-up of stains and oxidation is not just an aesthetic issue—it can significantly interfere with the operational efficiency of your molds and tools, cause unnecessary wear and tear, and even shorten their lifespan. With its deep-cleaning action, Zap-Ox™ helps maintain the molds and tools in an optimal state, reducing the risk of downtime due to maintenance, and extending the tool life in the long run.

Considering that replacing injection molds and tools can be a significant expense, the cost savings from reducing the need for replacements can be considerable. This makes Zap-Ox™ not just a cleaning agent but an investment toward a more productive, efficient, and cost-effective operation.

Safer for the Environment & Employees

A little Zap-Ox™ goes a long way, thanks to its concentrated, high-performance formulation. This means you use less cleanser per cleaning cycle, extending the product’s lifespan and resulting in significant savings over time. Fewer containers and less product waste also contribute to sustainability goals by reducing material usage and waste generation.

In addition, the versatile nature of Zap-Ox™ eliminates the need for multiple cleaning products. It has been designed to work effectively across various surfaces commonly found in injection molding setups. This simplifies the cleaning process and minimizes the clutter of having multiple specialized cleaning agents. This versatility reduces waste, cost, and complexity while maintaining a high standard of cleanliness across all surfaces.

In terms of user safety, Zap-Ox™ shines. Its non-toxic and non-caustic qualities make it a safer choice for employees and minimizes potential health risks associated with handling aggressive cleaning chemicals. In comparison to other cleaning agents, Zap-Ox™ sets a high standard. Zap-Ox™ is also NSF listed, so it’s safe for medical-grade and food-grade applications.

The benefits of Zap-Ox™ from Nanoplas are both powerful and far-reaching. Its exceptional cleaning efficiency improves the production process and significantly reduces downtime. By maintaining a high standard of cleanliness, Zap-Ox™ contributes to extending the lifespan of injection molds, leading to substantial cost savings over time. Moreover, its design incorporates crucial environmental and safety considerations, making it a safer option for the environment and workers. Zap-Ox™ represents a triple win: a champion cleaner, a guardian of injection molds, and a defender of the environment and workforce.

Order your free sample of Zap-Ox™ or Zap-Ox™ NG and experience the difference yourself.

by Nanomold Coating | Jun 5, 2023 | Recent Posts |

They say, ‘the devil is in the details,’ and nowhere is this more evident than in manufacturing operations. Minor aspects can significantly impact efficiency and, by extension, the bottom line. This principle holds true for all industries, especially plastic injection molding, where even minor improvements can yield significant benefits.

As a leading manufacturer of plastic injection molding coatings, greases, cleaners/degreasers, rust preventatives, mold releases, and stain removers, Nanoplas is helping redefine the landscape of injection molding. By turning attention to the fine details that often go unnoticed, Nanoplas optimizes the production line’s operational efficiency.

A More Efficient Injection Molding Process

In a typical injection molding operation, you could deal with six or more distinct types of mold maintenance products, each with its specific role. Juggling various products can lead to increased complexity, inventory management challenges, storage needs, waste generation, and costs. On top of this, there’s the need to ensure that training and safety measures are in place for handling each product.

Here’s the real game changer: Nanoplas products are designed for multitasking. Instead of a lineup of products for each application, you only need to lean on a couple of Nanoplas’ versatile mold maintenance solutions. This transition leads to a streamlined process marked by less clutter, reduced confusion, and ramped-up efficiency. Nanoplas injection molding products deliver:

- Simplicity: The fewer products you use, the easier it is to manage the overall process. This reduces complexity, making training and everyday operations more straightforward.

- Reduced Waste: Using multipurpose products reduces waste produced by excess packaging and unused or expired materials.

- Cost Savings: Fewer products often mean less money spent on purchasing, stocking, and replacing individual items.

- Space Savings: Reducing the number of products needed means you’ll require less storage space, freeing up room for other operations or creating a less cluttered working environment.

- Improved Efficiency: With fewer products to handle, switch between, and maintain, process efficiency can be significantly improved. This could lead to higher productivity and better quality control.

- Consistency: Using fewer products from a single manufacturer like Nanoplas ensures better compatibility and consistency across the process, reducing the risk of unforeseen reactions or complications.

- Increased Production Uptimes: You can significantly increase production uptimes by reducing the number of products used in the injection molding process. Traditional processes might require regular pauses for maintenance, such as re-greasing machine parts or dealing with failing molds, which can lead to considerable downtime and disrupt production schedules.

Empowering Your Employees

It becomes much easier to train employees when processes are simplified using versatile, multifunctional products like those from Nanoplas. They can focus on learning the core aspects of the process without getting bogged down in managing a vast array of mold maintenance products. Plus, a simpler, more streamlined process means fewer chances for confusion or mistakes, leading to a more positive work environment. Employees who feel confident and competent in their roles are less likely to seek employment elsewhere. So, not only does a simplified process make training a breeze, but it can also help reduce employee turnover, keeping your skilled workforce stable and reliable.

Streamlined Injection Molding Solutions

The streamlined injection molding process made possible by Nanoplas has far-reaching benefits that extend beyond the production line. It not only simplifies operations but also directly influences employee satisfaction. This satisfaction often translates into reduced employee turnover, keeping a stable and skilled workforce at the heart of your operations. And when your team is competent and content, they’re better equipped to maintain high levels of production efficiency. With Nanoplas, you’re not just investing in a solution to optimize your injection molding process but also fostering a happier and more productive workplace.

Experience the difference yourself. Try a free Nanoplas product sample today!

by Nanomold Coating | Apr 24, 2023 | Recent Posts |

Industrial machinery requires high-performance lubrication to operate efficiently, effectively, and safely. Min-Lube High-Performance Grease is an excellent choice for injection molding, offering exceptional protection and performance in severe environments and food and pharmaceutical-related industries. Let’s explore why Min-Lube High-Performance Grease from NanoPlas is a must-have for industrial machinery in the injection molding industry.

- Extreme Pressure and Wear Protection

The equipment and machinery involved in the Injection molding process are subjected to high levels of pressure and stress, which can result in wear and tear over time. This can cause the machinery to break down or malfunction, leading to costly repairs and downtime.

Min-Lube grease provides superior protection against extreme pressure and wear, ensuring that machinery operates efficiently and effectively for an extended period. This helps reduce equipment downtime, increase productivity, and reduce maintenance costs. The proprietary calcium sulfonate complex and carefully selected additive package offer excellent thermal, oxidative, and mechanical stability, making it ideal for severe environments.

- Wide Temperature Range

Injection molding machinery may be subjected to high temperatures due to plastic melting and low temperatures when the molded parts are cooled. Using grease that can withstand these extreme temperatures is critical to ensuring that the machinery operates efficiently and effectively, even under these extreme conditions. Additionally, grease with a wide temperature range can help reduce maintenance costs associated with switching lubricants due to temperature changes.

Min-Lube grease is designed to work effectively in a wide temperature range, making it suitable for various industrial applications. It remains stable at temperatures ranging from -15 °F to 550 °F, providing excellent protection and performance under high and low-temperature conditions, ensuring the machine can operate reliably throughout the entire injection molding process.

- Resistance to Water, Steam, Acid, and Chemicals

The injection molding process often involves using materials and substances that can cause corrosion, rust, and other forms of degradation to machinery and equipment. Using grease resistant to these substances can help ensure your machinery remains protected and in good condition, even when exposed to harsh environments.

Min-Lube grease is highly resistant to water, steam, acid, and many chemicals, making it an ideal lubricant for machinery operating in harsh environments. In addition, it provides excellent rust protection, ensuring that machinery is protected from corrosion, even in the presence of water and chemicals.

- Antimicrobial Protection

Injection molding machinery often operates in environments where moisture and organic matter are present, which creates a breeding ground for microbes. This can contaminate the machine and potentially the end product. Microbes can also break down lubricants and cause them to lose their effectiveness over time. Antimicrobial protection can help prevent this breakdown, ensuring that the lubricant remains effective for longer.

It contains Micronox® to provide antimicrobial protection, which is a groundbreaking technology that prevents degradation of the lubricant. This makes it a more long-lasting and effective lubricant for industrial machinery.

- Suitable for Food and Pharmaceutical Industries

The machinery and equipment used in the food and pharmaceutical industry must meet strict regulations and guidelines for cleanliness, hygiene, and safety. Any contamination or impurities in the products can have severe consequences for public health, making it critical to ensure that all machinery and equipment involved in the production process meet these standards.

Min-Lube grease complies with NSF Nonfood Compound Category Code: H1 and is designed specifically for lubrication in food and pharmaceutical-related industries, making it an ideal lubricant for machinery used in these industries. It does not contain metals, PTFE, or silicone, making it a safer and more reliable option than other lubricants.

Min-Lube High-Performance Grease is a must-have for industrial machinery, specifically in the injection molding industry. Its superior protection against severe environments, compliance with food and pharmaceutical regulations, antimicrobial protection, wide temperature range, and increased equipment lifespan make it an excellent choice for all industrial applications. By investing in high-quality lubricants like Min-Lube High-Performance Grease, you can ensure that your machinery operates safely, efficiently, and effectively for years to come.

Order your free sample and experience the Min-Lube difference for yourself!