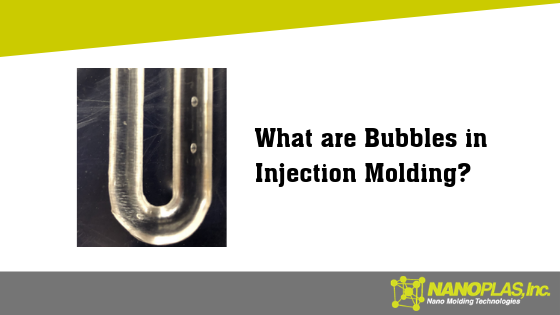

Are you experiencing bubbles during your injection molding processes? Let’s go through the possible causes—and fixes—to get rid of bubbles. What are Bubbles in Injection Molding? Bubbles, sometimes known as gas traps or blisters, are cosmetic defects that detract from...