Advantages of Mold Maintenance Injection molders around the world are striving to make their operations more efficient, and more productive. One area that is often overlooked when it comes to gaining such advantages is mold maintenance. A well-defined and consistent...

Easy Solutions to Splay Caused by Bleeding

Easy Solutions to Splay Caused by Bleeding Undesired bleed out in injection molding can be caused by—and lead to—a number of problems. One of the most common injection molding defects caused by bleeding is splay, which is often the result of an over-lubricated mold...

Molding for Manufacturing: Improving Startup & Minimizing Downtime

Coronavirus-related restrictions are beginning to ease up in Michigan and other states, so many sectors are getting back to work. Manufacturing is notably among them, and by extension, plastic injection molders. With employee safety top-of-mind, many plastic injection...

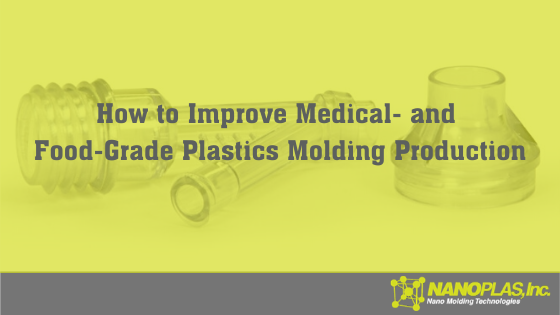

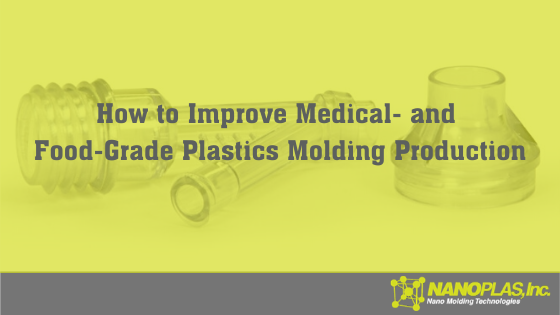

Tips for Increasing Production in Medical- and Food-Grade Plastic Injection Molding

Medical supplies. Food. Due to COVID-19, both are in extremely high demand and will be for the foreseeable future, making medical- and food-grade plastic injection molding extremely busy industries. How busy? Back in March, Forbes reported that the Director General of...

Five Trends in Injection Molding in 2020

This year’s plastic injection molding trends look to continue several of the big initiatives from 2019 in some exciting ways. As companies consistently strive to improve in all aspects of their businesses, increased efficiency and reduced downtime remain two of the...

Coronavirus: Will the Molding Industry Be Impacted?

Coronavirus: Will the Molding Industry Be Impacted? Most likely, the answer is yes. Wuhan and other parts of China shut not only their manufacturing down, but entire cities. That effect has rippled, as COVID-19 has spread and continues to spread, growing to become the...

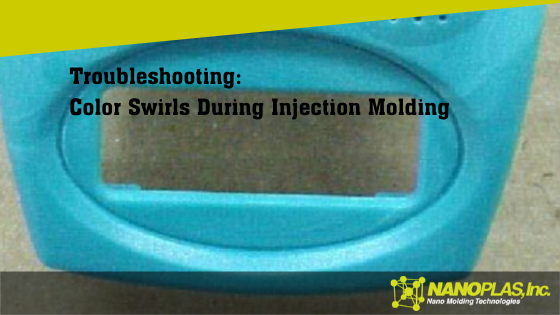

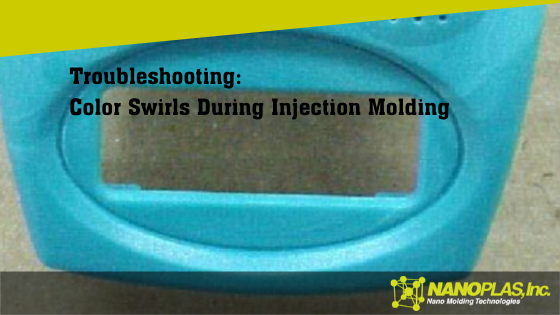

Fixing Color Swirl Problems with Molded Plastics

When color isn’t evenly distributed throughout a part, appearing as streaks, swirls or patches of discolored material, you’re probably looking at color swirls. Also known as streaking, color streaks and marbling, color swirls are occasionally misidentified as black...

Causes for Black Specks in Your Injection Molds

Causes for Black Specks in Your Injection Molds When you see black or brown specks on your molded part, you’re probably dealing with material that has been severely degraded. Sometimes called carbon buildup, black specks are sometimes mistaken as material...

4 Causes of Burns in Injection Molding

4 Causes of Burns in Injection Molding Sometimes known as dieseling or gas traps, burns in injection molding are literally that: burns. Often appearing as black, smutty deposits on the part and mold surface, these are spots at which the plastic has burned. Not to be...

Eliminating Cracks Within Injection Mold Parts

What Is Cracking in Injection Molding? When a part is physically fractured or broken, you’re experiencing cracking. Cracks usually occur due to post-molding conditions, but when troubleshooting cracking, you want to know exactly when the cracking is happening as it...

Advantages of Mold Maintenance

Advantages of Mold Maintenance Injection molders around the world are striving to make their operations more efficient, and more productive. One area that is often overlooked when it comes to gaining such advantages is mold maintenance. A well-defined and consistent...

Easy Solutions to Splay Caused by Bleeding

Easy Solutions to Splay Caused by Bleeding Undesired bleed out in injection molding can be caused by—and lead to—a number of problems. One of the most common injection molding defects caused by bleeding is splay, which is often the result of an over-lubricated mold...

Molding for Manufacturing: Improving Startup & Minimizing Downtime

Coronavirus-related restrictions are beginning to ease up in Michigan and other states, so many sectors are getting back to work. Manufacturing is notably among them, and by extension, plastic injection molders. With employee safety top-of-mind, many plastic injection...

Tips for Increasing Production in Medical- and Food-Grade Plastic Injection Molding

Medical supplies. Food. Due to COVID-19, both are in extremely high demand and will be for the foreseeable future, making medical- and food-grade plastic injection molding extremely busy industries. How busy? Back in March, Forbes reported that the Director General of...

Five Trends in Injection Molding in 2020

This year’s plastic injection molding trends look to continue several of the big initiatives from 2019 in some exciting ways. As companies consistently strive to improve in all aspects of their businesses, increased efficiency and reduced downtime remain two of the...

Eliminating Cracks Within Injection Mold Parts

What Is Cracking in Injection Molding? When a part is physically fractured or broken, you’re experiencing cracking. Cracks usually occur due to post-molding conditions, but when troubleshooting cracking, you want to know exactly when the cracking is happening as it...

How to Properly Apply Injection Mold Coating

There are three types of injection mold release coatings within our Nano Mold Coating family and two ways to apply them, depending on the type of coating you’re using. Our HC and HCF (the food-grade alternative to HC) coatings are applied in the tool room at...

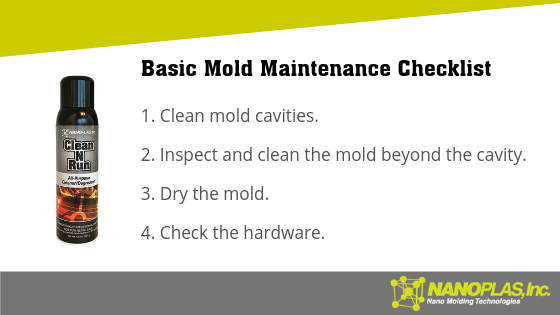

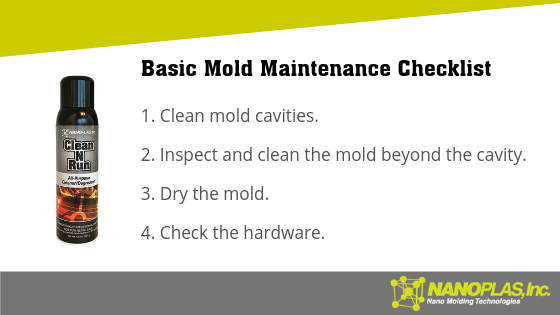

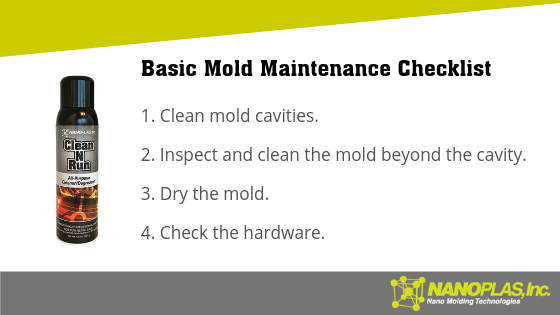

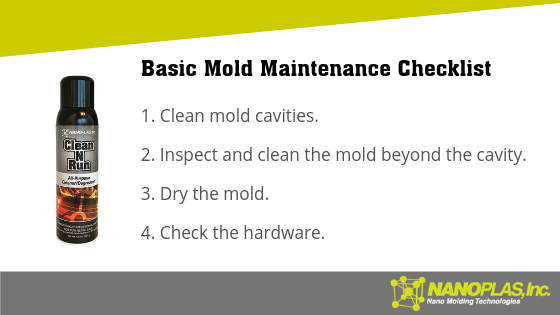

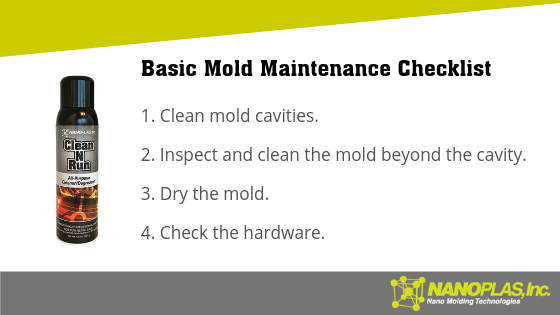

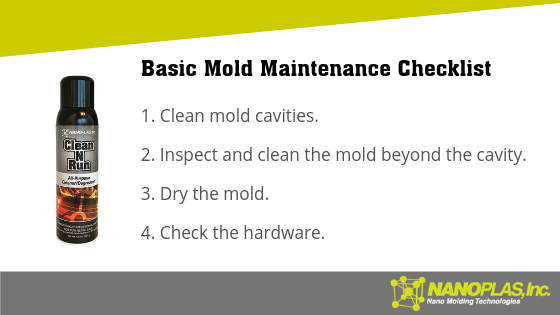

Basic to Advanced Injection Mold Maintenance Checklist

One of the most important aspects of injection molding, or anything involving machining, is making sure machines are running at peak performance. Any downtime cuts into efficiency and, ultimately, the bottom line. Prolonged downtime can lead to serious problems with...

Plastic Injection Molding Defects: Buildup

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them. What is Buildup? Sometimes called gas buildup or plate out, buildup in injection molding is easy to...

Plastic Injection Molding Defects: Burns

Welcome to our Plastic Injection Molding Defects series, where we will explain some common defects seen by injection molders and present ways to fix or prevent them. What are Burns? Sometimes known as gas traps or the dieseling effect, burns appear as black or brown...